In the grim distant future, there is only war.

I miss being creative. I really want to dust off the fun I would have designing costumes and building new parts of worlds I love. What better universe to do that in than 40k?

What is anyone in the grimdark future without a weapon to defend themself? Toast, that’s what they are. The Sisters of Battle are no different, often armed with chainblade and bolter running headlong into the heretic, alien and mutant.

Our sister encountered heavy heretic resistance on her mission as well as the last-standing Blood Ravens apothecary by chance. Their joint last stand with bolters in hand against the droves of chaos claimed the apothecary’s final breath. From that breath, the words “take my brothers home” fell from his lips, as his Absolver bolter pistol fell heavy from his gauntleted hand, and his fallen brothers’ gene-seed from the other. Our sister picks both objects and with the blessing of the Emperor escapes and is picked up by a Blood Ravens Thunderhawk roaring down from orbit. This fabled Absolver was gifted to the Sister for her incredible deed of bravery and service to the Chapter.

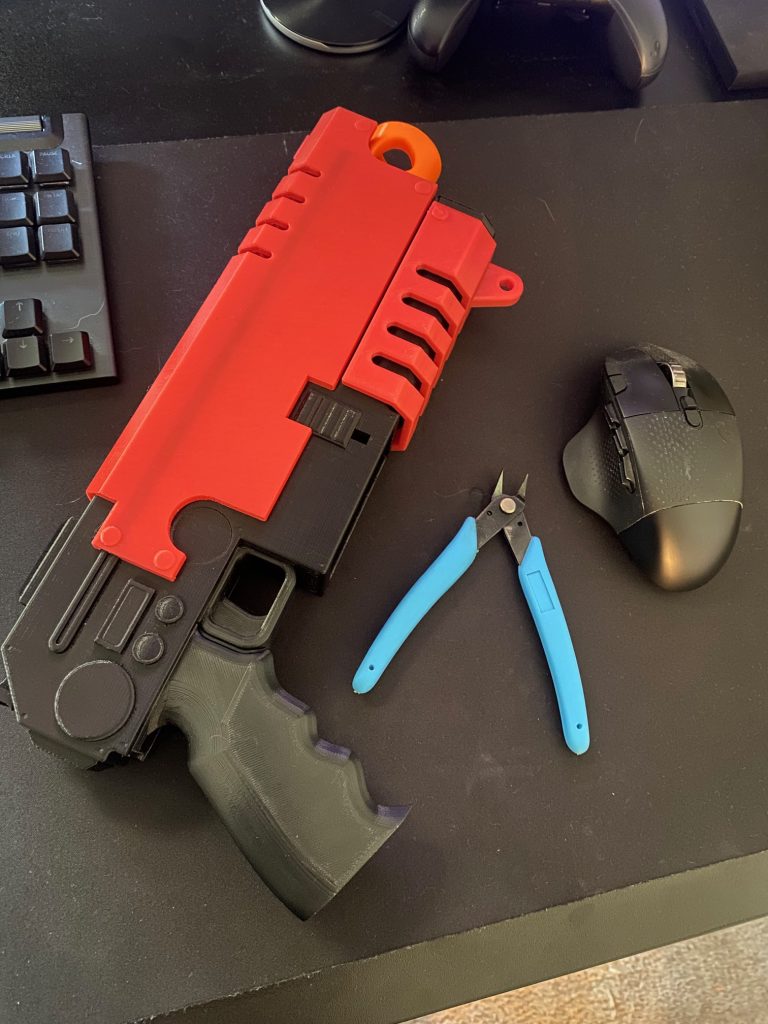

Modified to bear the heraldry of both Blood Raven and Sister of Battle, the Magpie’s Absolver has been reborn and purified, ready to tear into the flesh of those who dare incite chaos to the Imperium and its people.

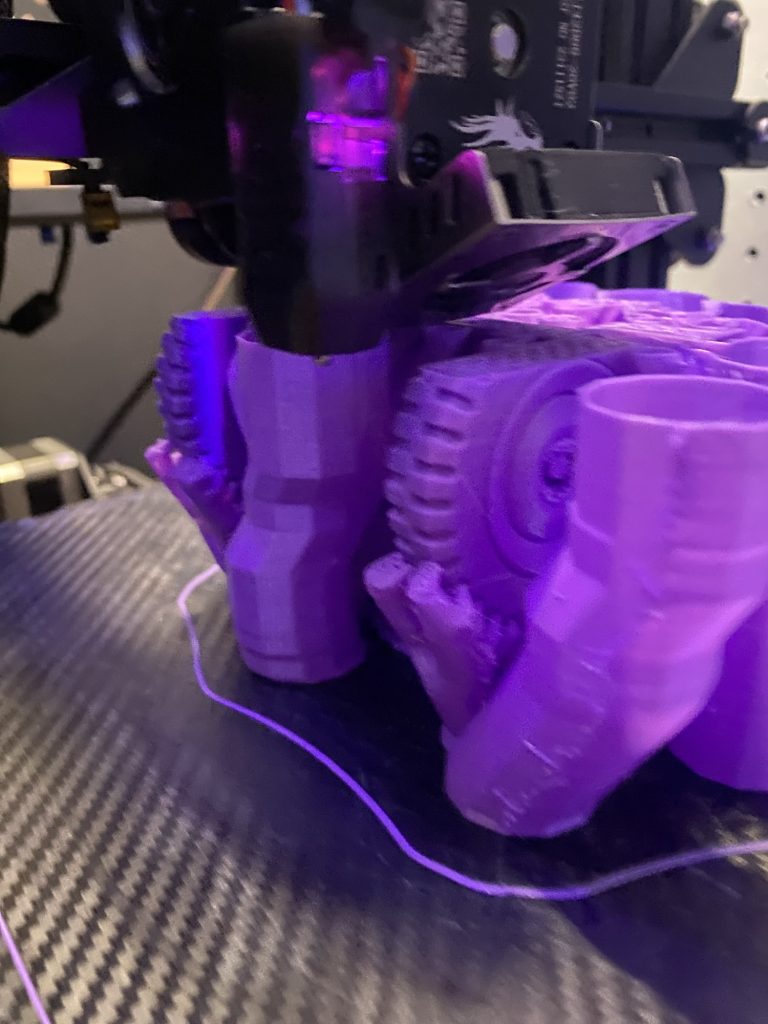

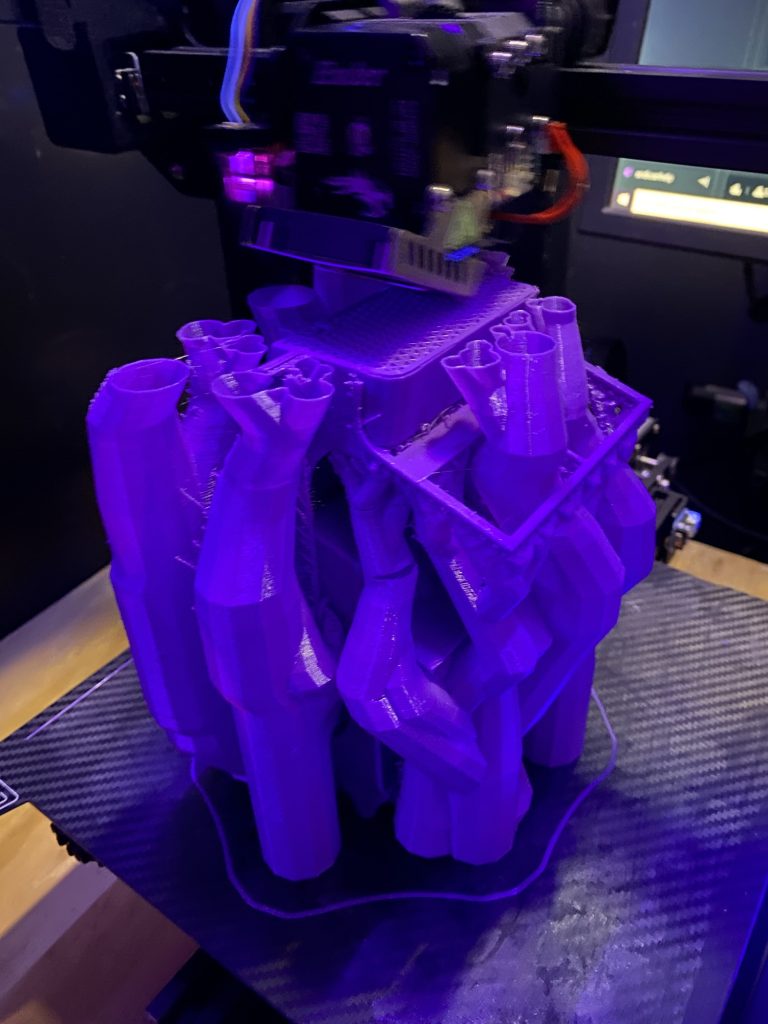

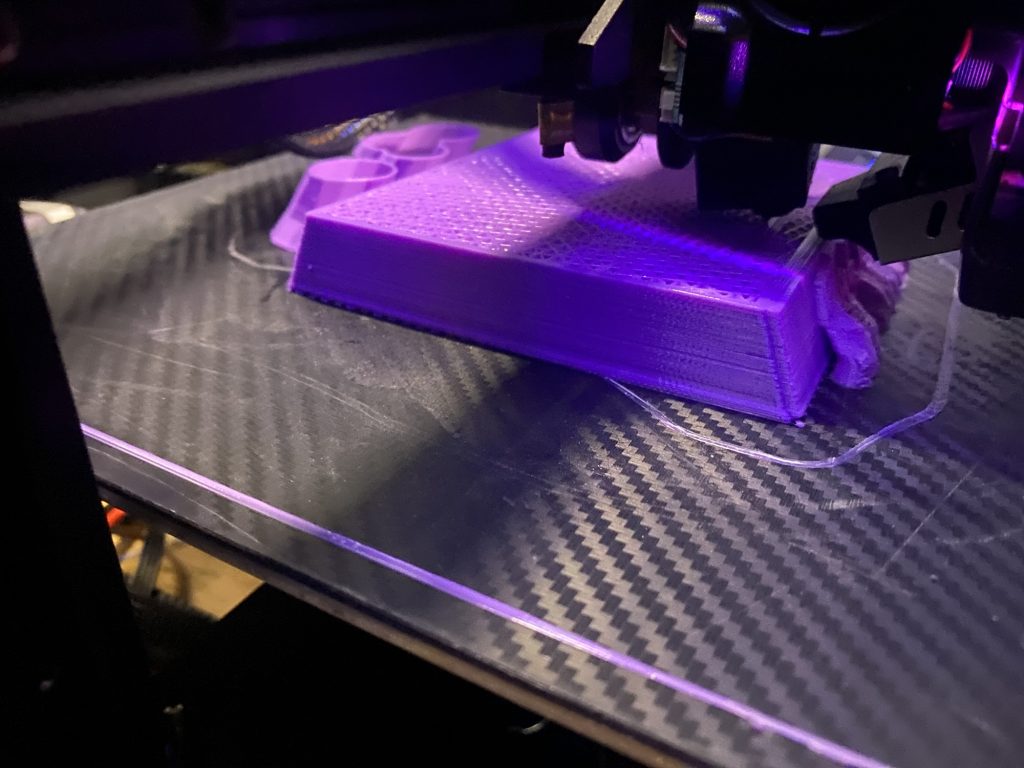

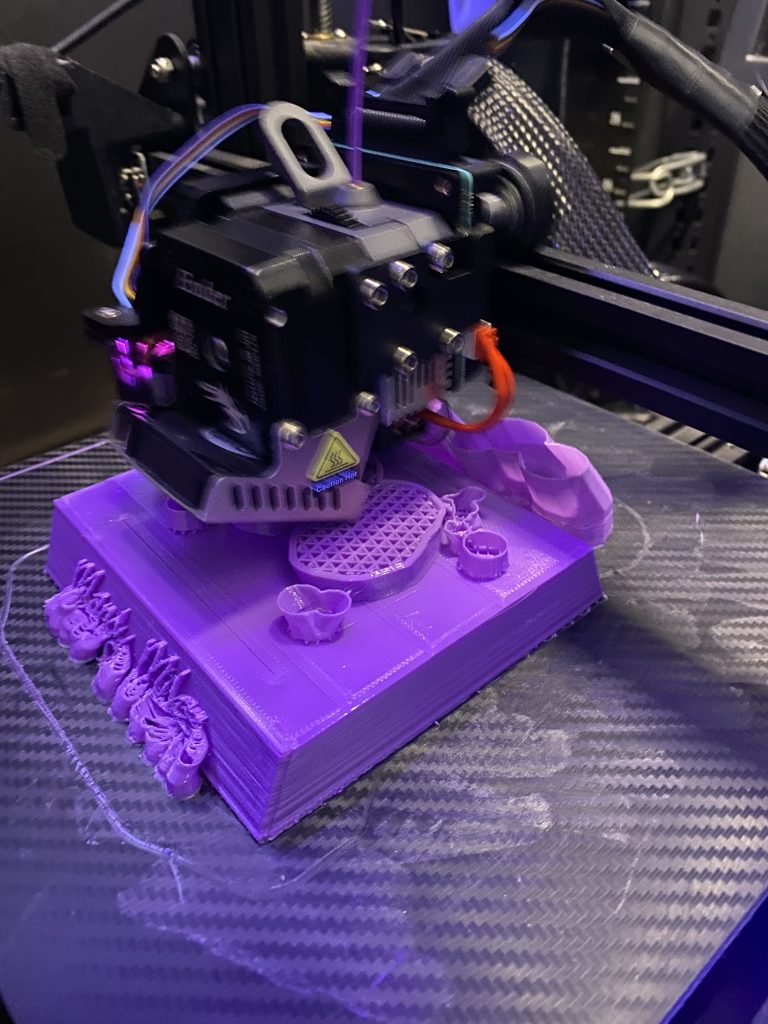

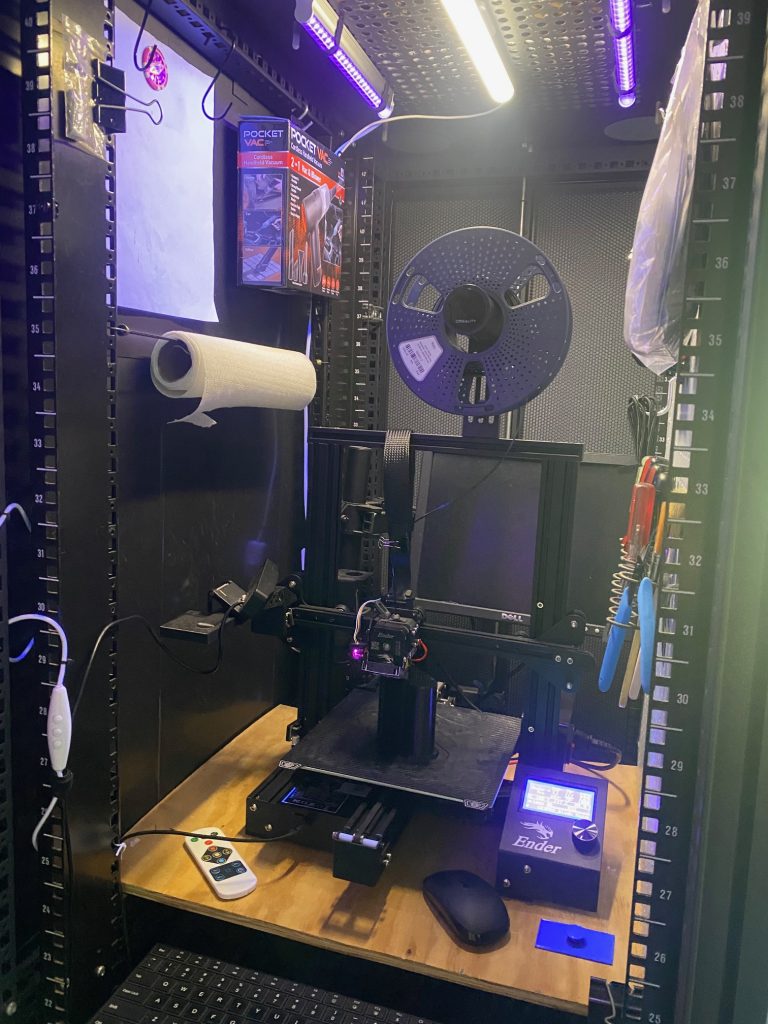

Now, about building this thing. It’s constructed out of about 16 different pieces, printed in PET-G for strength and smoothness. I used a 40% infill but could have likely gotten away with 30% (the prop weighs nearly 1.5kg!) It also measures over a foot in length!

Most of the parts are friction-fit, with a couple of smaller pieces requiring glue. The main body of the prop was printed in two pieces to accommodate my printer and is held together with the top rail of the prop. The first part that I printed was the bright orange tip for safety; the prop does not work but I wanted to be super safe.

I printed most of the prop in black PETG with accents in grey and red. To get the metallic look, I used a base of a spray-painted acrylic paint for a consistent coat, followed by a light brushing for contrast of some black and then silver foil. The prop features a printed purity prayer bearing the Sisters of Battle seal, as well as Blood Ravens heraldry and fleur de lis throughout.

The bolts that I printed for the prop do not fit in the magazine, and are for display/bandolier purposes. I will print some shorter ones to accommodate the shorter magazine length.

I think it turned out pretty great for such a large print! Let me know what you think!

-Andi